The new standard

in prototyping and pilot-series production

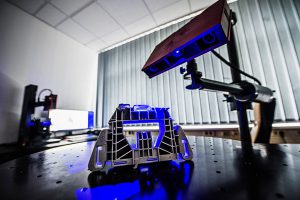

Topdown produces injection molding tools for prototypes, pilot production and small mass production. For more than 10 years we have customers in the automotive, consumer goods and capital goods industries. Our efficient project management, state-of-the-art manufacturing processes and high-quality tools guarantee our customers prototype parts in high quality.